Now, we buy rice seeds, but we did home seed-rising not so long ago. Home-raised seeds are sieved by the Salt water selection which is the selection of well-ripen seeds in the solution of NaCl or HN4SO4 at the specific gravity of 1.13. Egg can float on this concentration. Therefore, we use raw egg instead of measuring with the gravity meter. It is a farmers wisdom. We do Salt water selection for our self-harvest seeds.

Now, we buy rice seeds, but we did home seed-rising not so long ago. Home-raised seeds are sieved by the Salt water selection which is the selection of well-ripen seeds in the solution of NaCl or HN4SO4 at the specific gravity of 1.13. Egg can float on this concentration. Therefore, we use raw egg instead of measuring with the gravity meter. It is a farmers wisdom. We do Salt water selection for our self-harvest seeds.

The next step is the pre-germination before seeding. We soak rice seeds in a cool water ( at around 10℃ or less) for 10 to 14 days or more. The water temperature is raised to 28℃ two days before seeding and kept overnight so as to get uniform germination.

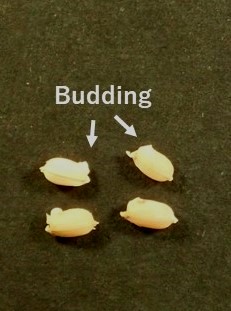

End-farm uses biological control of seed disinfection. When raising the water temperature, the germinating seeds are soaked in Taff-block solution, which is the Talaromyces flavus mixture. The Taff-block,Talaromyces flavus is not counted as the agrochemicals because of biological components (see Organic JAS, though written with Japanese). After the overnight dipping in 28℃ water, you can see the small budding about 1 mm, we call it as 'pigeon breast' condition. At this point, the budding seed is transferred to steaming treatment: without water but steaming at 28℃ for further promoting the rooting. Steaming treatment needs additional overnight, then gets ready for seeding.

End-farm uses biological control of seed disinfection. When raising the water temperature, the germinating seeds are soaked in Taff-block solution, which is the Talaromyces flavus mixture. The Taff-block,Talaromyces flavus is not counted as the agrochemicals because of biological components (see Organic JAS, though written with Japanese). After the overnight dipping in 28℃ water, you can see the small budding about 1 mm, we call it as 'pigeon breast' condition. At this point, the budding seed is transferred to steaming treatment: without water but steaming at 28℃ for further promoting the rooting. Steaming treatment needs additional overnight, then gets ready for seeding.

We use seedling box for the initial growth. This method is very popular now, but Ho-on-secchu-nawashiro had used before, which is the technology to grow seedlings at the corner of main field by covering whole bed with oiled-paper. The word 'Ho-on' means 'keep warm' and ' nawashiro' is 'seedling bed'. The 'secchuu' is 'to combine good factors' together. It based on the cool idea for warming with sun energy. When the paddy field is still cold such as in early spring, this technique warms the nursery bed by way of waterlogging, charcoal (black absorb much energy) covering and mulching with oiled-paper. This investment is due to the farmer's idea who lived in Nagano prefecture. As the spread of this technology, rice yield increased drastically. In 1960th, 30x60cm seedling box replaced this excellent system with the advent of transplanting machine.

We use seedling box for the initial growth. This method is very popular now, but Ho-on-secchu-nawashiro had used before, which is the technology to grow seedlings at the corner of main field by covering whole bed with oiled-paper. The word 'Ho-on' means 'keep warm' and ' nawashiro' is 'seedling bed'. The 'secchuu' is 'to combine good factors' together. It based on the cool idea for warming with sun energy. When the paddy field is still cold such as in early spring, this technique warms the nursery bed by way of waterlogging, charcoal (black absorb much energy) covering and mulching with oiled-paper. This investment is due to the farmer's idea who lived in Nagano prefecture. As the spread of this technology, rice yield increased drastically. In 1960th, 30x60cm seedling box replaced this excellent system with the advent of transplanting machine.

Let's return to our present seeding. Big farmers use the automatic seeder, which equipped soil feeder, seed dropper and the additional soil dropper on the belt conveyor. But for us, small farmers, primitive hand operating seeder is good. Prior to the seeding, we fill the 30x60cm box with soil by hand operation. Seeding is done on the hand operating belt conveyor, followed by soil covering with hand. These jobs are good enough for the senior neighbors. Including me, the senior persons are very powerful and trains our brain by working for these operation. I am always asking my neighbors " Please help us as long as you alive". They are kindly accept my offer as their body is in good health.As of now, every workers are powerful and the seeding job finishes earlier than my expected plan.

Let's return to our present seeding. Big farmers use the automatic seeder, which equipped soil feeder, seed dropper and the additional soil dropper on the belt conveyor. But for us, small farmers, primitive hand operating seeder is good. Prior to the seeding, we fill the 30x60cm box with soil by hand operation. Seeding is done on the hand operating belt conveyor, followed by soil covering with hand. These jobs are good enough for the senior neighbors. Including me, the senior persons are very powerful and trains our brain by working for these operation. I am always asking my neighbors " Please help us as long as you alive". They are kindly accept my offer as their body is in good health.As of now, every workers are powerful and the seeding job finishes earlier than my expected plan.

After seeding, nursery boxes are placed flat in vinyl-covered houseuntil 2.8 to 3.5 leaf-stage. It takes 3 to 4 weeks, and we have to carefully grow rice seedlings; temperature control by opening and closing the vinyl, watering several times a day and fertilizer application depending on the leaf-color. Note that modern nursery house equips automatic temperature and water control unlike our hand control. One week before transplanting, we spray liquid-potassium silicate, K2SiO3 for promoting plant tolerance to diseases, insects and other serious stress. Some agricultural paper reported that the application of K2SiO3 at the nursery stage is more effective than the application at the paddy field. Actually no blast control is required for our ordinal practice.

After seeding, nursery boxes are placed flat in vinyl-covered houseuntil 2.8 to 3.5 leaf-stage. It takes 3 to 4 weeks, and we have to carefully grow rice seedlings; temperature control by opening and closing the vinyl, watering several times a day and fertilizer application depending on the leaf-color. Note that modern nursery house equips automatic temperature and water control unlike our hand control. One week before transplanting, we spray liquid-potassium silicate, K2SiO3 for promoting plant tolerance to diseases, insects and other serious stress. Some agricultural paper reported that the application of K2SiO3 at the nursery stage is more effective than the application at the paddy field. Actually no blast control is required for our ordinal practice.

We wonder if we can continue the rice farming by this stuffs. Everybody becomes older year by year. In fact, it is the problem of Japanese agriculture. Although the government recommends big scaling through the subsidization. End_farm goes on the opposite direction: we continue small farming with elder persons. I am not sure if this way is the best or not, ha ha ha.

We wonder if we can continue the rice farming by this stuffs. Everybody becomes older year by year. In fact, it is the problem of Japanese agriculture. Although the government recommends big scaling through the subsidization. End_farm goes on the opposite direction: we continue small farming with elder persons. I am not sure if this way is the best or not, ha ha ha.

Back to the Top

Back to Farm practice

In parallel with the seedling preparation, we start field preparation. Rotary cultivation is the first step, then the tractor draw drive-harrow over the water-filled field twice; once roughly and second as a fine crushing. This rotary cultivation is calls as 'Shunko', wherein 'Shun' means Spring and 'ko' is the cultivation. The drawing harrow over water-filled field is called as 'Shiro-kaki'. The first harrowing is 'Ara-jiro' and the second as 'Hon-jiro', meaning that the rough harrowing first, then fine harrowing follows. It is an old man's wisdom to make flat the paddy field by using the water power. Dried soil is too heavy to make flat level. The harrow-drawing was due to the horse power before, and it is replaced by the tractor now. However, the technology still based on the same principle. It is an interesting point.

In parallel with the seedling preparation, we start field preparation. Rotary cultivation is the first step, then the tractor draw drive-harrow over the water-filled field twice; once roughly and second as a fine crushing. This rotary cultivation is calls as 'Shunko', wherein 'Shun' means Spring and 'ko' is the cultivation. The drawing harrow over water-filled field is called as 'Shiro-kaki'. The first harrowing is 'Ara-jiro' and the second as 'Hon-jiro', meaning that the rough harrowing first, then fine harrowing follows. It is an old man's wisdom to make flat the paddy field by using the water power. Dried soil is too heavy to make flat level. The harrow-drawing was due to the horse power before, and it is replaced by the tractor now. However, the technology still based on the same principle. It is an interesting point.

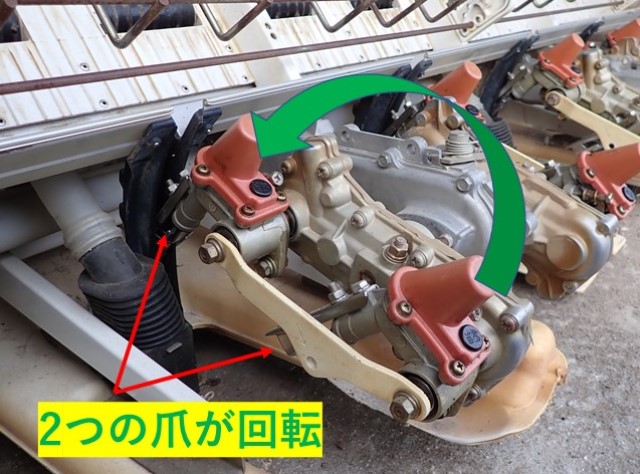

Now we use 4-rawed transplanter( see the photo). Rice seedlings grown in the nursery box ( mat shaped) are placed on the back tray of transplanter: two mats are set for one tray and totally 8 mats are shouldered on the back tray. In addition, four spare mats are put on the front trays, 2 by 2 way on the left and right, respectively. You can see very cool technologies at the seedling cutting; two finger-like needles rotated vertically and cut the seedling mat. Just at the soil insertion, the piston, attached itself to the finger, assisted to push the cut-piece into the soil. The model of this finger-like equipment is, of cause, due human hand. I love this delicate action and feel it as a real Japanese invention. On the other hand, I come up with another question, why direct seeding machinery does not realized widely in Japan. As of now it is quite rare unlike American broadcasting technology.

The rice transplanting, we call it as 'Taue', has been the biggest event in Japan. In the hand-planting age, many persons lined up in the paddy field to transplant and the line advanced after planting. The host person made a mark for the planting position by special instrument. Some person delivered many bundles of seedling in front of the moving line. Thus the work continued from the field to field for almost one month. This working style is called as 'Yui', a corporative mutual aid in the neighborhood. The 'Yui' system has been widely used not only for transplanting but also for many other events which needs much man power.

The rice transplanting, we call it as 'Taue', has been the biggest event in Japan. In the hand-planting age, many persons lined up in the paddy field to transplant and the line advanced after planting. The host person made a mark for the planting position by special instrument. Some person delivered many bundles of seedling in front of the moving line. Thus the work continued from the field to field for almost one month. This working style is called as 'Yui', a corporative mutual aid in the neighborhood. The 'Yui' system has been widely used not only for transplanting but also for many other events which needs much man power.

At the end of this work, peoples celebrate Spring Festival, called as 'Sanaburi', and pry for their good harvests. This tradition is gradually disappearing with the presence of machine-transplanting. Now almost all works are done by machinery transplanting, but we still need man power for supplying seedling mats, washing empty boxes and for making flat after the machine movement. In coupled with an old memory, farmers still want to work and pray with family by celebrating 'Sanaburi'. We would like to transmit this spirit for the future. For example, 'Eburi' is the flatting instrument of soil surface and need less power. My father was very good at handling it, but I am not. This must be inherited to me but I missed the chance yet. Not only inventing the cool instrument, but also handling technique must be transferred from generation to generation.

Back to the Top

Back to Farm practice

After the transplanting, missing plant (may occur at the rate of several %) must be supplemented by hand. It was popular before but is disappearing, because of the large-scale farming and due to the aging of workers. It is rather hard to walk in the paddy field. Although the cost effectiveness is low, there were two reasons why they do supplement; one is because of showing 'Good farmer' and the second reason is they want to expect higher yield. However, it does not affect the final yield because of the nature of rice such that the tillering covered the lack of neighbor plant ( the law of final yield constant).

After the transplanting, missing plant (may occur at the rate of several %) must be supplemented by hand. It was popular before but is disappearing, because of the large-scale farming and due to the aging of workers. It is rather hard to walk in the paddy field. Although the cost effectiveness is low, there were two reasons why they do supplement; one is because of showing 'Good farmer' and the second reason is they want to expect higher yield. However, it does not affect the final yield because of the nature of rice such that the tillering covered the lack of neighbor plant ( the law of final yield constant).

In the early growing stage, the insect-feeding damage is serious such of 'Dorooimushi', larvae of Oulema oryzae Kuwayama and rice water weevil, Lissorhoptrus oryzophilus. We apply the insecticide Admire GR on the seedling box. It is effective only almost 1 month in the field, and no residual component is detected at the harvest time. Before the heading, no other insecticides are applied.

We apply herbicide 1 week and 3 weeks after the transplanting . At the same time, we start the ridge mowing. It is really a hard job and the spider more play an important role as my companion worker. We do mowing at least 3 times before heading and the additional mowing just before the harvest. An acrobatic way is the rope controlling-mow on the long and keen slope, which is not recommended by the manufacturer. Brush cutter is effective for the corner clean up.

We apply herbicide 1 week and 3 weeks after the transplanting . At the same time, we start the ridge mowing. It is really a hard job and the spider more play an important role as my companion worker. We do mowing at least 3 times before heading and the additional mowing just before the harvest. An acrobatic way is the rope controlling-mow on the long and keen slope, which is not recommended by the manufacturer. Brush cutter is effective for the corner clean up.

As the whole process, the most popular cropping here in 'Nishina-mikuriya' starts with transplanting in May, heading at the early August, and the harvest follows in late September to early October. Our End-farm rice is in accordance with the ordinal way. Just before the maximum tillering stage, we make several furrows to enhance the drainage. I use riding furrow-maker which is similar to the bike. Because of this similar shape, this machine is called 'Tamen-rider'. 'Tamen' means 'on the paddy field'. We have a story about this naming such that we had a TV hero named 'Kamen-rider', who is the masked rider and fight with the villain.'Tamen-rider' is a parody of 'Kamen-rider', and some manufacturer sales its product on the trade-named 'Tamen-raider'. It is true, though ours is not the one. But we also call it as the 'pseudo-Tamen-rider'. I guess it an amazing story.

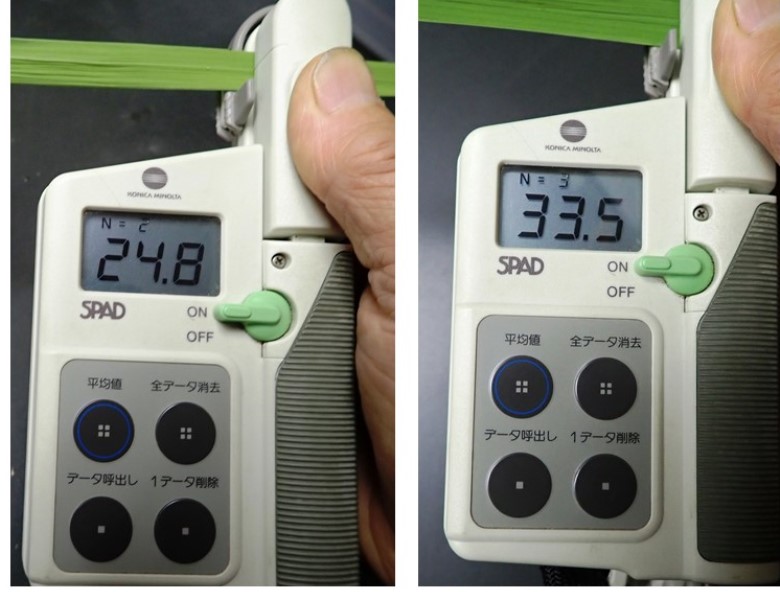

The maximum tillering stage is almost 1 month prior to the ear-heading. The young panicle forming stage is just after the maximum tillering stage. According to The theory of V-shaped rice cropping by Dr. Matsushima, it is important to cut off the nitrogen (N content) in the soil for good ripening afterword. He was born in Nagano prefecture and is famous in the Japanese society of crop science. Regardless of doing his V-shaped cropping or not, Rice taste is reversely correlated with Nitrogen content of the grain at harvest. Therefor the N content is very important to decide the amount and timing of top dressing if the N-shortening happened. We use SPAD measure to estimate nitrogen content in the leaves; above 25 as no N top-dressing, whilst lime superphosphate, Ca(H2PO4)2 & CaSO4 is top-dressed. Recently the capsulated fertilizer is recommended because top dressing is not required. The encapsulated granules contain nitrogen that melts out along with the temperature increase when rice reached at the timing of top-dressing. It is a labor-saving technology and easy for handling by the old ages, however the plastic capsule causes the environment pollution. We are trying to avoid causal factors.

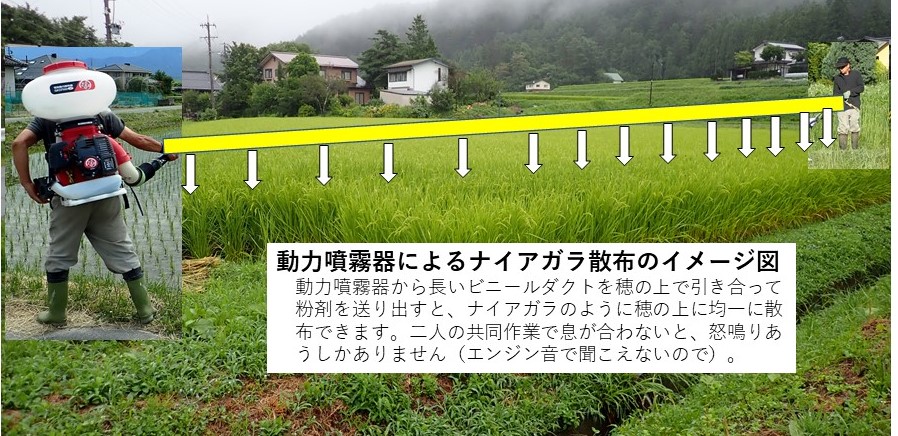

Rice heading here is at early August, and the ripening starts. Milk ripening stage is the timing of stink bug, Heteroptera control. Consumers do not prefer damaged grain, and a grade down may happen if black sucking marks remains. It does not affect on the taste but because of this preference we have to control this insect. We apply Kirrapu powder, non-'neonicotinoid' insecticide, by shouldering sprayer with long duct, we call it as 'Naiagara', on the field surface (see the picture). 'Niagara' is named after Niagara fall. Two persons are required and my wife and I work together. Although this powder is not the 'neonicotinoid', it also affect the mortality of honey bees. We hope alternative insecticide developed, but we do not have another choice as of now. Yet, we have to provide our meal to my customers.

Rice heading here is at early August, and the ripening starts. Milk ripening stage is the timing of stink bug, Heteroptera control. Consumers do not prefer damaged grain, and a grade down may happen if black sucking marks remains. It does not affect on the taste but because of this preference we have to control this insect. We apply Kirrapu powder, non-'neonicotinoid' insecticide, by shouldering sprayer with long duct, we call it as 'Naiagara', on the field surface (see the picture). 'Niagara' is named after Niagara fall. Two persons are required and my wife and I work together. Although this powder is not the 'neonicotinoid', it also affect the mortality of honey bees. We hope alternative insecticide developed, but we do not have another choice as of now. Yet, we have to provide our meal to my customers.

Back to the Top

Back to Farm practice

Our harvest relays on the Mr. Combine. The name of Combine comes from the corporation of Binder and Harvester. The cutting part mostly based on the binder technology, and the threshing and self-running parts on the 'Harvester'. The body size can be decided due to the grain tank-capacity and the power of driving. Our combine is 3 rowed type, meaning the harvest 3 raw at one time. This machine can work for all the field over, except for the corners. Therefore we need some helpers to cut and clean the corners by hand.

Our harvest relays on the Mr. Combine. The name of Combine comes from the corporation of Binder and Harvester. The cutting part mostly based on the binder technology, and the threshing and self-running parts on the 'Harvester'. The body size can be decided due to the grain tank-capacity and the power of driving. Our combine is 3 rowed type, meaning the harvest 3 raw at one time. This machine can work for all the field over, except for the corners. Therefore we need some helpers to cut and clean the corners by hand.

When the buzzer told us full-tank sign, we have to drive the combine to the ridge where small truck, 'Keitora' is waiting and let the grain out into the 'Carrier' on the truck-bed. Our combine is 3 raw harvest type, and 2 times full tank let the carrier full of container. And the dryers can accept 3.5 times by this carrier, which amount correspond to 30a harvest. The full grain on the truck may exceed the carrying limit of 'Keitora'(350kg). The policemen kindly excuse us. Thank you.

Truck carried rice grains go into Drier. The 50℃ wind blows indirect on the grain , when the surface of the grain retained at around 20℃~30℃ temperature. This temperature is close to the room temperature. When the water content of the grain got down to 18%, the dryer stops for several hours to keep the water contents constant, then work again to almost 15% moisture. Thus, dryer keeps grain surface as close as the natural condition, most probably the evenness is better.

Truck carried rice grains go into Drier. The 50℃ wind blows indirect on the grain , when the surface of the grain retained at around 20℃~30℃ temperature. This temperature is close to the room temperature. When the water content of the grain got down to 18%, the dryer stops for several hours to keep the water contents constant, then work again to almost 15% moisture. Thus, dryer keeps grain surface as close as the natural condition, most probably the evenness is better.

After finishing the job, the dryer let the grain out into the Stocker (you may see it at the left of dryer) and leave the grain at least several hours to further fit uniform temperature. Almost 30a harvest makes the dryer full tank and 2 times drying can be kept in the stocker. Based on this count, 10days are enough for 3 ha harvest, however the reality is a bit beyond the counting. When it is rain or the stocker is full because of consecutive rainy days, we are not able to go harvest.

By the way, do you remember the TV program ' Shitamachi-Rocket', wherein incredible scene was broadcasted; several combine did harvest in a heavy rain. Do you believe this is possible in reality? The answer is 'No'. Even super-combine is developed, the threshing drum and related equipment do not work in the rain. Our stocker is convenient and helpful for waiting the rain over.

Dehulling is due to husking machine. Usually we do husking in the evening or early morning, because harvest must be done for non-wet ear. Unless completing the husking job, the dryer and the stocker do not get empty. When the husking machine operated, husked grain flow out into sieving machine continuously. When the grain passed through the sieve, 1.80-1.85mm mesh assortment is obtained. Grain bagging is due to scaled for each 30.6 kg in a strong paper bag. Upon carrying 30kg bag, the lifter called 'Rakuda-kun' elevate it up to my west height, and we pile the bags on the pallet. The 30 bags on the 5 layered pallet is the unit of hand lifting. We handle almost 500 bags in one season. 'Rakuda-kun' is really helpful and gentle on the waist. The pile up grain bags are moved by hand lift, and piled up again on the truck bed, then carried to 'Dozo' then piled up again. 'Dozo' is the warehouse with mud wall suitable for the humid Japan.

Dehulling is due to husking machine. Usually we do husking in the evening or early morning, because harvest must be done for non-wet ear. Unless completing the husking job, the dryer and the stocker do not get empty. When the husking machine operated, husked grain flow out into sieving machine continuously. When the grain passed through the sieve, 1.80-1.85mm mesh assortment is obtained. Grain bagging is due to scaled for each 30.6 kg in a strong paper bag. Upon carrying 30kg bag, the lifter called 'Rakuda-kun' elevate it up to my west height, and we pile the bags on the pallet. The 30 bags on the 5 layered pallet is the unit of hand lifting. We handle almost 500 bags in one season. 'Rakuda-kun' is really helpful and gentle on the waist. The pile up grain bags are moved by hand lift, and piled up again on the truck bed, then carried to 'Dozo' then piled up again. 'Dozo' is the warehouse with mud wall suitable for the humid Japan.

Back to the Top

Back to Farm practice

We get the residue of husking machine in a net bag, called as 'Nukaron', so as to handle easily afterword. If we are rich enough and have a husk stocker, we do not need to change net bags so often during husking. But we do not have it and pray for no husking machine trouble.

We get the residue of husking machine in a net bag, called as 'Nukaron', so as to handle easily afterword. If we are rich enough and have a husk stocker, we do not need to change net bags so often during husking. But we do not have it and pray for no husking machine trouble.

The End_Farm's essential idea is such that rice must be a excellent gift from nature, so the residual plant parts must be returned to the field as much as possible. Therefore, the residual husk must be returned to the field. I modified the broad caster more suitable for broadcasting the voluminous husk. The husk is rich of nutrients for plants such as SiO2. There are much SiO2 in nature and we apply further SiO2 , however this factor is easy to become water-insoluble. The SiO2 in rice husk is the one which absorbed by rice plant and is more suitable for re-absorption. Once we distribute it over the field, less commercial SiO2 can be applied, though the cost of oil consumption by tractor is not negligible if the cost-performance is considered.

The End_Farm's essential idea is such that rice must be a excellent gift from nature, so the residual plant parts must be returned to the field as much as possible. Therefore, the residual husk must be returned to the field. I modified the broad caster more suitable for broadcasting the voluminous husk. The husk is rich of nutrients for plants such as SiO2. There are much SiO2 in nature and we apply further SiO2 , however this factor is easy to become water-insoluble. The SiO2 in rice husk is the one which absorbed by rice plant and is more suitable for re-absorption. Once we distribute it over the field, less commercial SiO2 can be applied, though the cost of oil consumption by tractor is not negligible if the cost-performance is considered.

Upon the work of moving the bag, hand-made slope and powered-hoist help the job. Once the 3 'Nukaron' bags of husk is throw in the broadcaster, we drive the tractor to the field then broadcast it. Three times broadcasting is done for each 10a.

After finishing husk delivery, the modified broadcaster changes his style; return to the original. And the broad caster works again for distributing the soil conditioner over the field. We mix several nutrient factors and supply over the soil. The next step is the rotary cultivation, if the weather is still not so cold. Depending on the weather, the cultivation might be done in the next spring, case by case.

After finishing husk delivery, the modified broadcaster changes his style; return to the original. And the broad caster works again for distributing the soil conditioner over the field. We mix several nutrient factors and supply over the soil. The next step is the rotary cultivation, if the weather is still not so cold. Depending on the weather, the cultivation might be done in the next spring, case by case.

The voice of Happy New Year is the sign of opening next season. We cut and clean the extra branch of Ume, apple, grape and pear gradually. When the weather is good for outside job, we will work, but we will take rest when the weather is bad. It is the natural cycle. In March, the rice cropping starts again. We are repeating this farm cycle year by year, but 10 years count only 10 times, even 50 years cropping just as 50 times trial, ha ha ha.

Back to the Top

Back to Farm practice

Small cultivator is very convenient for the small area cultivation. This cultivator equipped reversing rotary in addition to the forward rotary. We use reversing rotary for weeding at first, because of its sharrow cultivation. After the rough weeding, we switch the forward rotary for further deep digging. When the vegetable species requires the ridge, the rear cover of the rotary can be used as a harrow for making the furrow. You may not understand its excellence, but the idea is very cool. Some lady developer came up with this idea.

Small cultivator is very convenient for the small area cultivation. This cultivator equipped reversing rotary in addition to the forward rotary. We use reversing rotary for weeding at first, because of its sharrow cultivation. After the rough weeding, we switch the forward rotary for further deep digging. When the vegetable species requires the ridge, the rear cover of the rotary can be used as a harrow for making the furrow. You may not understand its excellence, but the idea is very cool. Some lady developer came up with this idea.

Back to the Top

Back to Farm oarctice

It is an old machine but still working in a active duty. Here is foot threshing machine. The history of threshing started very old; probably by foot stepping on then, followed by the hitting with mallet. In the Edo era in Japan, 'Senbakoki' was developed, which is a hand threshing instrument by pulling the rice bundle on the aligned needle. Afterword new machine appeared, that is, foot driving drum-thresher ( see the picture). This threshing drum might be the basic idea for engine driving harvester, hence combine later on.

It is an old machine but still working in a active duty. Here is foot threshing machine. The history of threshing started very old; probably by foot stepping on then, followed by the hitting with mallet. In the Edo era in Japan, 'Senbakoki' was developed, which is a hand threshing instrument by pulling the rice bundle on the aligned needle. Afterword new machine appeared, that is, foot driving drum-thresher ( see the picture). This threshing drum might be the basic idea for engine driving harvester, hence combine later on.

'Toomi' is the wind selector or winnower made of wood. 'Too' means an old Chinese age and 'mi' means winnower: the winnower introduced from China (see the picture). The old style was man driven type, but now metal type is sold, some are motor drive. The picture shows the man who is hand turning the fan, then the wind blows from right to left. The heavier the grain drop out from the right exit, while lighter grain fly longer distance and drop out from the left exit. The immature grain fly out of the instrument. The principle is very simple but is very convenient for the job of small amount selection. Furthermore the strength of the wind can be controlled by the fan speed. Because of this simplicity, not only rice grain but also many other seeds can be cleaned easily and effectively.

'Toomi' is the wind selector or winnower made of wood. 'Too' means an old Chinese age and 'mi' means winnower: the winnower introduced from China (see the picture). The old style was man driven type, but now metal type is sold, some are motor drive. The picture shows the man who is hand turning the fan, then the wind blows from right to left. The heavier the grain drop out from the right exit, while lighter grain fly longer distance and drop out from the left exit. The immature grain fly out of the instrument. The principle is very simple but is very convenient for the job of small amount selection. Furthermore the strength of the wind can be controlled by the fan speed. Because of this simplicity, not only rice grain but also many other seeds can be cleaned easily and effectively.